GUOSHI Assemblying parts introduction

An assembly line is a manufacturing process (often called a progressive assembly) in which parts (usually interchangeable parts) are added as the semi-finished assembly moves from workstation to workstation where the parts are added in sequence until the final assembly is produced. By mechanically moving the parts to the assembly work and moving the semi-finished assembly from work station to work station, a finished product can be assembled faster and with less labor than by having workers carry parts to a stationary piece for assembly. What do GUOSHI assembly workers do? Assembly workers are responsible for putting together the various parts of a particular product. Their job may involve assembling one set of components or the finished product. What types of skills do assembly workers need for GUOSHI? Assembly workers must have good dexterity, basic math skills, and the ability to read and understand blueprints or manuals. They must have strong mechanical and technical skills, stamina to be on their feet for long hours, and strength to lift heavy parts during assembly. They must also have color vision to identify different colored wires, tabs and components. What are the educational requirements for an assembly worker of GUOSHI? Entry-level assembler jobs typically require a high school diploma or GED. More advanced positions may require specialized training and experience and/or an Associate’s degree from a technical school. What types of tasks do assembly workers perform in GUOSHI factory? Assembly workers prepare and position parts for assembly, ensure each component is fastened together correctly, check connections and log any discrepancies. They read measurements, verify specifications, measure completed components and assemble parts to approved specifications. Assembly workers maintain and service equipment, troubleshoot equipment malfunctions, ensure quality control, maintain supply inventory, record actions on production forms and communicate with other stations on the assembly line to ensure accuracy, speed and efficiency. What types of equipment do assemblers use in GUOSHI company? Assembly workers use a variety of hand tools, mechanical instruments and calibration equipment to put together products.

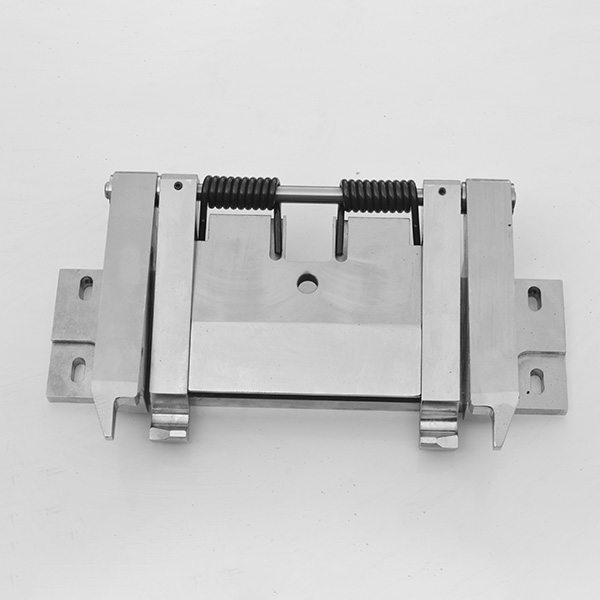

Metal assemblying s with plating

Steel fabrication parts

Furniture locks with nickel plating